Wear repair of mill gearbox bores: current status and future perspectives with AI integration

September 5, 2025

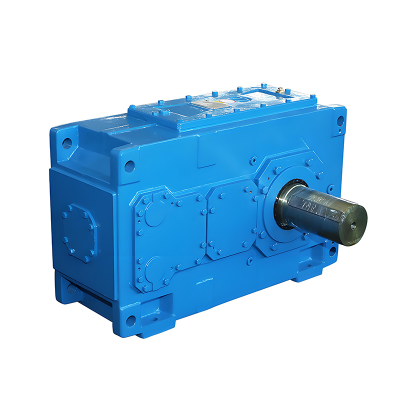

In the booming industrial field, Industrial Gearboxes, serving as the cornerstone for the operation of a wide array of machinery, are witnessing an ever - increasing prevalence as all kinds of industrial equipment find broader applications. Metallurgical rolling mill gearboxes, functioning as the linchpin components within rolling mills—an indispensable part of industrial production—are experiencing a gradual emergence of gear box bore wear issues. Consequently, wear repair technology has emerged as a focal point of concern.

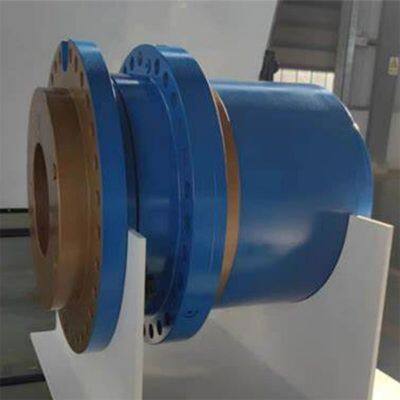

Among the diverse range of gearboxes, standard industrial gearboxes are ubiquitously employed in numerous industrial facilities. Their reliability and performance are the bedrock for seamless production processes. When addressing the repair of rolling mill gearbox bore wear, a well - established and more mature repair process has been extensively adopted.

The first step is the pretreatment phase. Here, the wear - affected parts of the rolling mill gearbox, much like those in mining heavy duty gearboxes that endure the harsh and demanding working conditions in mining operations, are meticulously cleaned and ground. This meticulous preparation paves the way for subsequent repair procedures. Subsequently, surface treatment is executed to fortify the bond between the repair materials and the substrate. This step is of utmost importance as it guarantees the long - term efficacy of the repair work.

Material mixing follows, which is pivotal in ensuring that the repair material attains its optimal performance. Just as in the maintenance of specialized gearboxes for petrochemicals, where the unforgiving chemical - laden and high - pressure environment demands top - notch repair materials, procuring the right material blend for the rolling mill gearbox is of critical significance. Once the materials are well - mixed, they are evenly applied to the worn - out parts.

After that, the material is left to fully cure, thereby forming a stable repair layer. This cured layer equips the repaired gearbox to endure the mechanical stress during operation. Finally, the reinstallation is completed, enabling the equipment to resume normal operation, much like the process of restoring a machine tool power gearbox to full functionality after maintenance. This seamless restoration is crucial for maintaining the productivity and efficiency of industrial operations, whether it's in the metal - rolling industry, mining sector, petrochemical plants, or machine - tool manufacturing facilities.

Looking ahead, more advanced repair technologies and high-performance materials are expected to emerge as a result of in-depth research in materials science and continuous innovation in engineering technology. At the same time, with the rapid development of artificial intelligence (AI) technology, its integration into the equipment monitoring and analysis system can realize real-time, accurate monitoring of equipment conditions, timely detection of potential problems and early warning for the efficient and stable operation of industrial production to provide stronger protection.

Share